|

STRUCTURAL WEAKNESS (Times 3) |

|

Why haven't Railtrack or the Health and Safety

Executive acted on a report of a damaged railway bridge?

This report can't answer the question; but it does point out how serious the consequences of neglect could be, and it does provide evidence of this neglect. There is an urgent need to audit Railtrack's procedures and to investigate why the Railway Inspectorate are so ineffectual. At the time of writing, over ten months after the alarm was originally raised, over two months after the HSE were alerted to the inaction of people they're supposed to be monitoring, nobody knows if bridge 176 is safe. Dozens of deaths could result. What you see here is version 1 written on 27th October 1998. There have been subsequent developments. |

||||||||

|

||||||||

| To save time loading images they are initally shown using a very economical but crude form. It is possible to get better images by clicking on the adjacent buttons. NOTE: You will probably need to have your browser set to 'automatically load images' for these upgraded images to appear when requested. |

| Contents |

| 1 | Summary |

| 1.1 | In January 1998 the end wall of brick underbridge number 176 on the East Anglian main railway line at Witham, Essex was seen to have a crack in it. This was indicative of a shear failure caused by the pressure of the embankment above pressing outwards. During the next six months, when fortunately the crack does not appear to have worsened, Railtrack seem to have ignored the situation despite being informed about it. In August the HSE were asked to investigate this apparent indifference. Two months later they do not appear to have done so. |

| 1.2 | This report concludes that Railtrack are negligently endangering lives, and that the 'guarantee of safety' that should be provided by the RI/HSE is not working either. |

| 1.3 | The recommendation is that now the existence of organisational failures has been established, that an independent enquiry should analyse the causes of these weaknesses and recommend solutions. |

| 2 | Introduction |

| 2.1 | Cracked bridge and official indifference |

| This report is the result of the author's personal observation of structural weakness in bridge and the subsequent attempts to ensure that incipient failure did not become actual failure. Railtrack, the organisation that should have acted when alerted appears to have done nothing about this for 9 months. The Railway Inspectorate (RI) of the Health and Safety Executive (HSE) treated this with such urgency that after two months and three letters there is still no signs of the bridge being supervised. | |

| 2.2 | Location... |

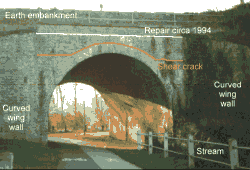

| Witham lies roughly midway between London and Ipswich on the East Anglian main line. Bridge 176 carries the railway over a foot/cycle path and culvert. At this point the railway is on a considerable embankment with houses at the foot from the bridge towards the town and station. | |

| 2.3 | ...Too close for comfort |

| The site of the Rivenhall derailment of 1997 is 3 Km further down the line. Appendix B contains a summary of the causes and pictures of the results as a reminder of the seriousness of the consequences of poor standards of track maintenance. | |

| 2.4 | Scope of investigation |

| The author, 'a member of the public' trained as an engineer, maintains an interest in many aspects of engineering but does not practice as an engineer. Lack of such data as plans, operating procedures and organisational charts does not invalidate the conclusions. Therefore this report concentrates on showing where problems exist rather than analysing them in detail. (That should be the subject for another investigation.) |

| 3 |

Bridge construction and current state (Vagueness in this description is due to lack of access to official records.) |

| 4 | Will anyone investigate? |

| 4.1 | Railtrack? |

| Railtrack were informed on the 9th January 1998. The only action that appeared to occur as a result was a standardised acknowledgement. | |

| 4.2 | HSE? |

| The HSE/RI was informed on August 7th 1998 that nothing appeared to have happened and would they investigate. Over two months later, after chase letters on 10th September and 15th October there are still no signs of any action by Railtrack. HSE/RI claim to be dealing with the situation. | |

| 4.3 | Me? |

| Is it not reckless for me to have let things take their own course for so long? Well in one way yes but as it appears we have two weak organisations who are indifferent then it becomes a question of balancing the risk of catastrophic failure against obtaining sufficient evidence of structural weakness in the organisations. I'm making a point of checking for any signs of movement weekly on the assumption the failure won't be instantaneous. | |

| Correspondence details are given in appendix C. |

| 5 | Discussion |

| 6 | Conclusions |

| 6.1 | Bridge 176 needs a survey |

| 6.1.1 |

The current state of the bridge is:

|

| 6.1.2 | The consequences of failure are at the least going to be highly disruptive to the East Anglian main line. If a derailment occurred the result could be many people killed. The seriousness of the consequences of failure being so great mean that more than hunches are required to confirm it is safe. |

| 6.1.3 | Until bridge 176 is properly surveyed and kept under routine surveillance the bridge must be considered suspect. |

| 6.1.4 | The neglect of this matter so far means that some independent auditor will be required to check the survey findings and to ensure that any future work or procedures are carried out. The public can't have trust in either Railtrack or HSE/RI particularly when both organisations will be keen to cover up any errors. No scrutiny equals no confidence. |

| 6.2 | Organisations need investigating |

|

I'm one of those funny people who thinks that an incipient structural failure is a

matter requiring urgent investigation. In a single word ACTION.

I also have this odd idea that Railtrack should have a culture of safety including people who appreciate the relative significance of matters rather than a PR and rule-issuing administration. Strange to say, I also find the HSE/RI inability to act inexcusable. More than that, I can not understand how this situation could possibly happen. There must be something very seriously wrong with this organisation. |

| 7 | Recommendations |

| 7.1 | Railtrack need to survey bridge 176 urgently. |

| 7.2 | The survey and Railtrack's plan of action need to be available to the public. |

| 7.3 | HSE/RI to investigate why Railtrack have taken no action to date |

| 7.4 | An independent enquiry is carried out into the way HSE/RI operate. |

| 7.5 | The results of recommendation 7.3 are independently audited. |

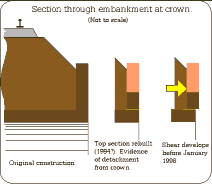

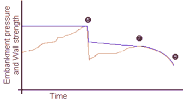

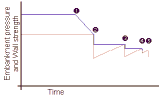

| A | Engineering matters explained |

| You do not need to be an engineer to appreciate the substance of this report.

However as there might be some debate about the true significance of a shear

crack in brickwork the reader may have more confidence discussing these

matters if they're aware of the basic vocabulary and some of the principles

involved. (Besides, if you understand these few matters you have grasped the

essence of structural engineering.)

Some words are used by engineers in a more specialised sense than in common English. The most important distinction is between STRESS and STRAIN. |

|||||||||

| STRESS | How much pressure is applied to a component. (Stress - I have tried to refer to engineering stress in the text as 'pressure' for an easier read and to avoid confusion with strain.) | ||||||||

| STRAIN | How much a component is deformed. Often, but not always, strain is measured as a how much longer or shorter a component gets, typically as a percentage. In engineering, stress and strain are never interchangeable. | ||||||||

| PRESSURE | Defined as force per area just like, for instance, tyre pressures. I have used a slightly less strict definition for the purposes of clarifying the explanation. | ||||||||

Stress can be applied to a component in different ways:

SHEAR is sliding. When books on a shelf fall over together, one book shears against the next leaving steps where the top of one meets the next. |

|||||||||

| CRACKS | Cracks, being what make things break have been studied in detail. In many

cases their behaviour can be understood and progress predicted with

confidence. Cracks have a very important characteristic: The longer the crack

the easier it grows...getting longer...getting easier and so on, faster and faster

until it cuts right across the material and the object breaks. For example hold a

sheet of newspaper by the top corners and pull apart. It is very difficult to start

a tear down the middle, but once started it becomes easier and easier. This

means that if you spot a crack when it's small you may have time to do

something about it. It also means that cracks below a certain size in certain

situations will never get worse. Cracks can look quite unsightly but still be

safe.

A TENSION CRACK is where the material is being pulled apart. A tension crack only has strength if being compressed. The only thing keeping the two sides of the crack together otherwise is the material left joined at the ends which now has to take the load that was previously being taken by the cracked area. A SHEAR CRACK is where the material has been sheared. See figure 1 in section 3.2. A shear crack might have a little residual strength but no sane engineer would rely on it. |

||||||||

| CREEP | Creep is where a material gradually deforms. Lead for example is quite creepy. It's not just soft but will 'flow' over time even under its own weight. Creep is normally a slow and predictable process and is often insignificant particularly with construction materials. Where creep in construction can be a problem is with soil, as the leaning tower of Pisa illustrates. Water can turn sound ground into a slurry with hardly any strength at all. | ||||||||

| SAFETY FACTOR |

A FACTOR OF SAFETY is an insurance against things not quite turning out as

you calculated. It is very rare for the stresses and strengths to be known with

precision. The safety factor allows for these margins of error. This can be a

matter of making something three times as strong as 'should be necessary in

an ideal world'. From the day the structure is built the forces of nature start

work. Rust, roots, rainwater are natural forces. Neglect, modification and

loading beyond the original specification can also cause deterioration. The

more confidence you have that you're nowhere near the limits of strength the

less attention you have to pay to ensuring you keep within them. And vice

versa: Old ladies take extra care not to fall over because their bones become

brittle with age.

However to calculate a factor of safety you need to understand what's going on in engineering terms. This is called a MODEL. (Possibly a scale model, but mostly drawings and mathematics.) In some cases eyeing up the situation will do - "How many screws should I use to put this shelf up" in others, particularly where lives are at risk you either make sure you know exactly what's going on or insist on bumping up the safety factor to cover your ignorance. SAFE DESIGN is the art of making something safe in the first place and also making sure that potential problems can be spotted before they become major ones, and/or trying to minimise the effects if it should fail. There are trade-offs between these and other factors. For example the price paid for lightweight and critical aeroplane components is expensive in-service inspection. If you can't inspect then you need a soft-fail facility in the same way as motorcycles have a reserve tank instead of fuel gauges. Notice that this is SAFE USE, which is specified initially at the design stage in the operating instructions (If the engineer is any good - for "use" read "mis-use"). |

| B | 1997 Rivenhall derailment |

|

An Ipswich bound containerised freight became derailed at Rivenhall on 23rd

September 1997. A number of wagons left the track at high speed. A great

deal of infrastructure was damaged and services were severely disrupted. The

cause appears to have been poorly maintained track.

Version 1 : The above is based on press reports. Version 2 will include a summary of the official report and results of a court case arising due to be heard at Harlow Magistrates on the 3rd of November. | |

| C | Correspondence |

| 9th Jan '98 | PF telephone to Railtrack |

| |

| 7th Aug | PF letter to HSE |

|

On the 9th January 1998 I telephoned Railtrack and reported that bridge 176, at

Witham on the East Anglian main line (a couple of miles from last year's Rivenhall

derailment) was showing signs of structural distress. The retaining wall above the

north portal was cracked and it was not a cosmetic matter. This last point was

emphasised. Both portals have had the top part of their retaining walls repaired

(estimate) 4 years ago. The crack is below this new work. (The problem appears on

the south portal retaining wall to a much less noticeable extent.)

In the seven months since then there has been no signs of telltales, datum points, or any other instrumentation so you may want to investigate what steps Railtrack have taken to look at this matter. Should there be a structural failure and derailment on the same scale as Rivenhall then a dozen houses at the bottom of the embankment would be squashed. Naturally, I am not expecting an immediate reply, but I would like answers to the following specific questions:

| |

| 19th Aug | HSE (Mark J Hashim) to PF |

|

[Thank you formality] Your letter is receiving attention and a reply will be sent to you in due course. | |

| 10th Sept | PF to HSE (Mr M Vowells) |

|

Mr Vowells appears on letterhead of 19th Aug

as Divisional Administration Manager Railtrack bridge 176, Witham

"... in due course." | |

| 14th Sept | HSE (Mark J Hashim) to PF |

|

"Thank you for your letter of 10 September 1998. Your letter has recently been

passed to the inspector concerned who is dealing with your enquiry.

Please accept my apologies for the delay in sending a full reply which is due to our continuing enquiries." | |

| 15th Oct | PF to chief executive of HSE |

|

Over two months and no hint of progress

Railtrack bridge 176, Witham 7th August I write the attached. 19th August you say : "... in due course." 10th September I ask how are you getting on? 14th September you reply with a 'we're doing something' letter but no details. It is now over two months since drawing your attention to what might be 1) a serious structural defect 2) a possible lack of safety systems at Railtrack. If you lived at the bottom of the embankment I think you'd want some better reassurances than you've been able to provide so far. This is the second time this year I have had to complain. In the first case your Chelmsford office knew that by the time they got round to having to do anything the responsibility would no longer be theirs so wasting my time and showing complete disregard for the safety of the public. That was a disgrace. Now in this instance I'm assuming that nothing has been done either. Passing papers around is pathetic. Perhaps you'll be good enough to tell me: 1) what progress your staff have made so far in this matter. 2) when you think you'll be able to answer the questions posed. A copy of this letter has been sent to my MP. | |

| 19th Oct | HSE(Secretary to the Director General) to PF |

| Acknowledged receipt of my letter of 15th. "A reply will be sent to you shortly" | |

| 19th Oct | HSE(Mark J Hashim) to PF |

|

Further to my letter of 14 September 1998, I am writing to inform you that the

inspector concerned is currently dealing with your enquiry and is making enquiries

with Railtrack to establish what steps they have taken to ensure that this bridge is in

a safe condition.

Once again, please accept my apologies for the delay in responding and a full reply will be sent to you as soon as it is possible. | |

| Postscript : 25th October. Still no signs of any Railtrack action. |